“Resilience” is the word most often heard in supply chain discussions; however, Point B believes it’s about reinvention with best practices in mind. How do you build, or reinvigorate, a supply chain you can trust? This strategic imperative requires a foundational framework embedded with innovation, collaboration, sustainability, agility, and talent development to adequately address and mitigate disruptions. Given the critical nature of aerospace and defense products, any interruption in the supply chain can have significant consequences, including production delays, increased costs, and compromised national security. Such disruptions can be avoided through a reinvention focused on preparedness, readiness, and adaptability.

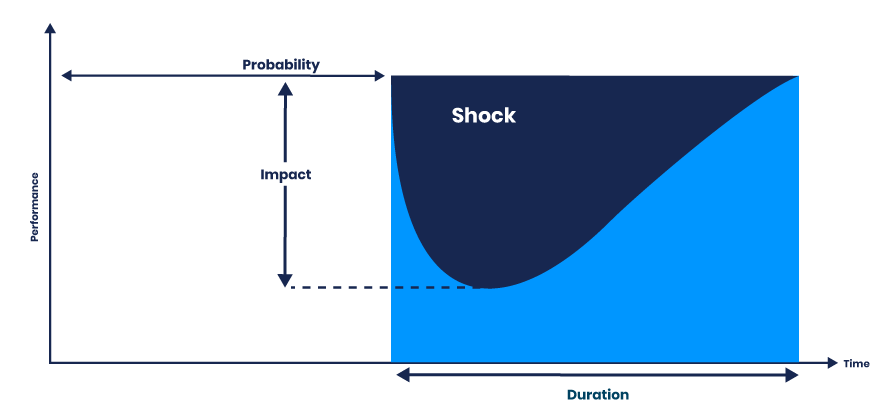

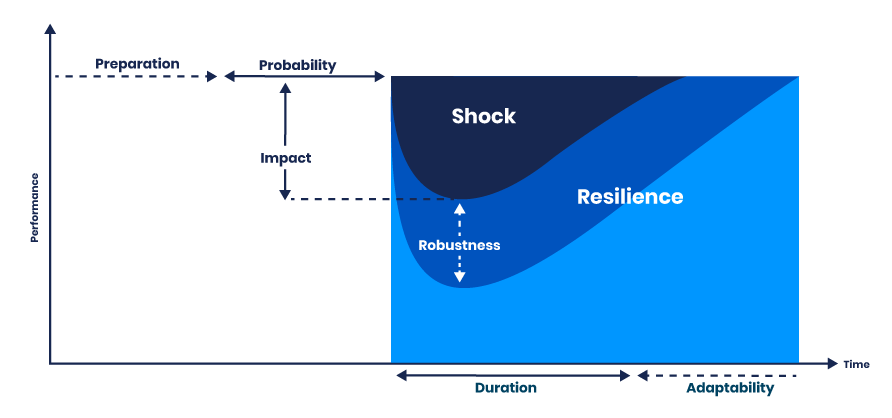

The Disruption Model

Disruptions to supply chain operations threaten performance quality, reputations, and revenue generation. Disruptions to the supply chain can take many forms, such as a weather event (e.g., hurricane), economic (e.g., trade barrier or recession), labor impact (e.g., strike, unexpected departure of a key person, or epidemic), or geo-political events (e.g., conflict or military action). These create logistical challenges and shortages in raw materials and part availability.

The foundational framework to create a resiliency plan to overcome disruptions should include:

- Preparation for the Probability - “How prepared in advance are you?”

- Readiness for the Impact - “How ready is your supply chain now?”

- Adaptability for the Duration - “How adaptable are you?”

How do these 3 things reduce or overcome disruption? (See graphic). Preparation reduces the chances of disruption. Readiness reduces the impact when disruption occurs. And lastly, adaptability reduces the time back to supply chain stasis.

Strategic investments for a trustworthy supply chain

Preparation is easier with quality data and built-in redundancy

Should any disruption to the supply chain occur, preparation reduces the probability that the disruption will meaningfully decrease business performance. These are proactive investments to make before a disruption arises. Ultimately, good preparation extends the time frame between the disruption and any impact on the organization’s supply. Preparation techniques include some combination of:

Data-enabled risk identification

Your high standards for your products and their delivery should extend into your supply chain data. Quality data across the supply chain ecosystem will provide insight into risks and vulnerabilities, like an early warning system.

Scenario planning

Advanced digital twin modeling, control tower, and pre-identified scoring criteria can help you anticipate the effects of a disruption.

Diverse suppliers and vendors

When disruption impacts an individual or a segment of partners, support capacity can be redistributed to unaffected partners.

Talent and processes redundancies

Clear succession planning prevents the absence or loss of leaders or subject matter experts from disrupting decision-making. The aging workforce is a big challenge for engineering in aerospace. The talent pipeline for experienced engineers is extremely low, and developing internal talent can take years. You can use a built-buy-borrow method to have a balanced approach.

Well-defined standard operating procedures (SOPs) close the knowledge gaps in the event of key talent loss to remain compliant. Since aerospace and defense is highly regulated, it’s critical to document for better knowledge transfer. Stringent requirements must always be met, even during workforce transitions.

Prevent the absence or loss of key operators from interrupting operations by employee cross-training and/or training local resources on critical operations that, if impacted, would cause a pervasive disruption.

Business continuity playbook

Proactively prescribe checklists and activities to be executed during specified disruptions including defined metrics and data that will enable and guide decisions. Creating rapid response teams that snap into place once certain criteria are met increases the speed at which emergency planning and response can begin.

If you’re a Tier 1 or 2 supplier, consider M&A activity to control upstream supply

The right part at the right place at the right time is becoming increasingly complex and challenging for supply chain leaders. Preparation that balances the management of materials, talent, and data will combat disruptions.

If you are looking for control of materials, lead times, or delivery commitments, then mergers and acquisitions may be a consideration for growth, greater control, and increase in market share.

Readiness means quickly pulling the right control levers in a crisis

Readiness minimizes the volume or amount of impact. Think of readiness as the reactive levers you can control while experiencing a crisis to mitigate damage to your operations.

Readiness techniques include:

- Stockpiling and spare management - Susceptible and/or critical inventories should be considered for stockpiling.

- Create supplier inventory agreements for key items - Contract negotiations with if/then clauses can protect certain item shortage particular for items that are historically difficult to source.

- Integrated business planning - The use of inventory management formulas and techniques allows for a rapid and more accurate inventory management response to a disruption. However, available and accurate data define these formulas and techniques. Do you have quality data and analytics to make better decisions faster

- Capitalize on those preparation investments - Utilize your business continuity playbook and workforce redundancy plans as needed.

While traditional economic order quantity (EOQ) and safety stock are good measures during normal supply-and-demand times, organizations that do best are the ones that are vigilant in examining where they have soft spots or vulnerabilities in their supply chains.

Adaptability comes from clear prioritization

Finally, adaptability is the ability to reduce the duration it takes to resume operational performance to pre-disruption levels. This often requires a quantitative and qualitative approach to understand when to revert specific actions taken during the disruption. Certain actions may not be sustainable or optimal over a long period of time and, if left in place for too long, could begin to decrease operational performance. Adaptability techniques that organizations may use include some combination of:

- Managing exceptions-based metrics based on organization’s tolerance of disruption risk

- Clear prioritization criteria. While it may seem obvious, complex or multi-siloed organizations are susceptible to losing sight of how disruptions impact the entire organization. Step back and reprioritize based on the timing of your logistics and firm-wide strategic objectives.

- Capitalize on investment in the Preparation phase

- Create supplier capabilities and flexibly skilled workforces through a build-buy-borrow workforce mentality

- Act on the relationships with partners and third-party logistics (3PL)

Available reactive options diminish once a disruption begins. The investments made for preparation reap continued benefits within the readiness and adaptability strategies. Most of the tactics in the adaptability approach rely on tactics planned in the preparation phase. Adaptive companies take precautions early and re-evaluate often.

The reality of trade-offs

Developing a resilience strategy requires making tradeoffs. Too often, supply chain leaders consider resilience planning as a nice to-have – until disaster strikes. It’s imperative to be deliberate about resiliency, which means creating capabilities in priority areas and understanding which areas to invest in. It can be helpful to think of each resilience capability alone and as a combined effort, with some options reinforcing 2 or 3 resilience capabilities. Resilience options with overlapping benefits are where supply chain leaders should prioritize investments to maximize return.

Fundamentally, building a resilience strategy requires selecting the desired balance between those options that promote efficiency versus those that will promote conservatism. Tactics that support resilience, such as stockpiling supplies and developing secondary supplier relationships, can incur greater expense and capacity, but provide some insurance against supply chokepoints. Just-in-time planning, e.g., traditional Lean activities or cross-training a smaller pool of employees, can expose the organization to more single points of failure but generate greater flexibility and speed. The answer is to find the right mix of tactics that protect your organization, supply chain and overall firm strategy.

A thoughtful supply chain resilience strategy that prioritizes and balances proactive preparation, reactive readiness and adaptability can make the difference between a company succumbing to the chaos of the next disruption or thriving.

Ultimately, can you trust your supply chain?

If the answer is “no”, then use these approaches to enable your supply chain to be less reactive and more resilient.

RELATED INDUSTRIES

RELATED SOLUTIONS